Polished Concrete Pricing Compared to Carpet, Tile, LVT/VCT, Hardwood and Other Floor Coverings

by Tom Cramsie

Polished Concrete Floors vs. Epoxy

Pricing often plays a key role in deciding the best flooring option. In all, polished concrete flooring is on the lower end of the pricing spectrum despite its long service life and low-maintenance requirements.

For consumers, pricing often plays a role in decision making, from deciding where to live all the way to simply deciding where to eat dinner. Flooring is no different. While function, look, durability and maintenance will be considered factors, pricing will also play a role in the decision making process.

Polished Concrete Pricing Factors

Polished concrete pricing is based on several factors. The largest driving forces are capital expenditures for the polishing equipment and labor costs. A typical 30” grinder and vacuum set-up will cost anywhere from $35,000 – $70,000. On jobs greater than, say, 3,000 square feet, more than one grinder and vacuum may be required to meet project timelines. Depending on if the equipment is propane or electric powered, a generator may be required. Most electric industrial grinding equipment requires 3-phase power. If the appropriate 3-phase power is not available on-site, a generator will be required. Generators range anywhere from $25,000+ for a used unit to $75,000+ for a new unit. Oftentimes, companies will rent a generator for around $2,000 per week versus trying to purchase one. Additional equipment will involve polyurea joint pumps, joint saws, hand grinding equipment and vacuums and autoscrubbers, among others. It is not uncommon for a commercial/industrial polishing outfit to arrive at a job with $100,000+ worth of equipment.

Pricing often plays a key role in deciding the best flooring option. In all, polished concrete flooring is on the lower end of the pricing spectrum despite its long service life and low-maintenance requirements.

For consumers, pricing often plays a role in decision making, from deciding where to live all the way to simply deciding where to eat dinner. Flooring is no different. While function, look, durability and maintenance will be considered factors, pricing will also play a role in the decision making process.

For consumers, pricing often plays a role in decision making, from deciding where to live all the way to simply deciding where to eat dinner. Flooring is no different. While function, look, durability and maintenance will be considered factors, pricing will also play a role in the decision making process.

Labor is the other major driving force in polished concrete pricing. Polishing concrete is a lot of things but fast is not one of them. Completing a proper polish job with metal grinds, hand edge work, patching and joints, cleaning, guarding and burnishing is a long process. Many of our projects last several weeks to months. As an estimator, my job is to accurately approximate how long the project will take to complete. Estimating labor costs is much more difficult than material estimating. We generally know joint filler, densifier and guard application rates. It is much more difficult knowing how hard the concrete will be, how many other trades will be working in the area, site access, etc.

Raw materials certainly play a role in polished concrete pricing but are not the primary driving costs. Basic raw materials include diamond tooling, patching materials, joint filler, densifier, guard and sundries. Polished concrete will have less raw material requirements than tile, hardwood flooring, carpet, Luxury Vinyl Tile/Vinyl Composite Tile (LVT/VCT) and terrazzo.

Options

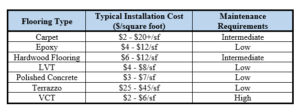

There is a wide variety of flooring options based on the desired look and use. Below is a simple table detailing the most common flooring options and associated costs. There are certainly many more options available and cheaper or more expensive options for each of those listed in the table. Prices will vary based on area size, the number of rooms, material quality, complexity, etc.

Maintenance Costs and Considerations

Beyond initial installation costs, maintenance requirements and costs should be the other consideration when selecting flooring options. We’ve discussed in past blogs the relatively low-maintenance requirements of polished concrete. Polished concrete maintenance requirements should be in line with hardwood flooring and LVT/VCT which is to say frequent mopping should be the primary requirement. Some commercial stores wax their VCT which becomes a routine maintenance requirement in order to maintain a high gloss finish. Hardwood flooring will require periodic sanding and sealing to remove scratches (especially if large dogs are part of the equation!!).

Conclusion

Pricing affects many, if not all, purchasing decisions. While there are a variety of flooring options available, polished concrete proves to be one of the most affordable and low-maintenance options. A high-quality polished concrete floor will demonstrate an extended service life with minimal maintenance costs.