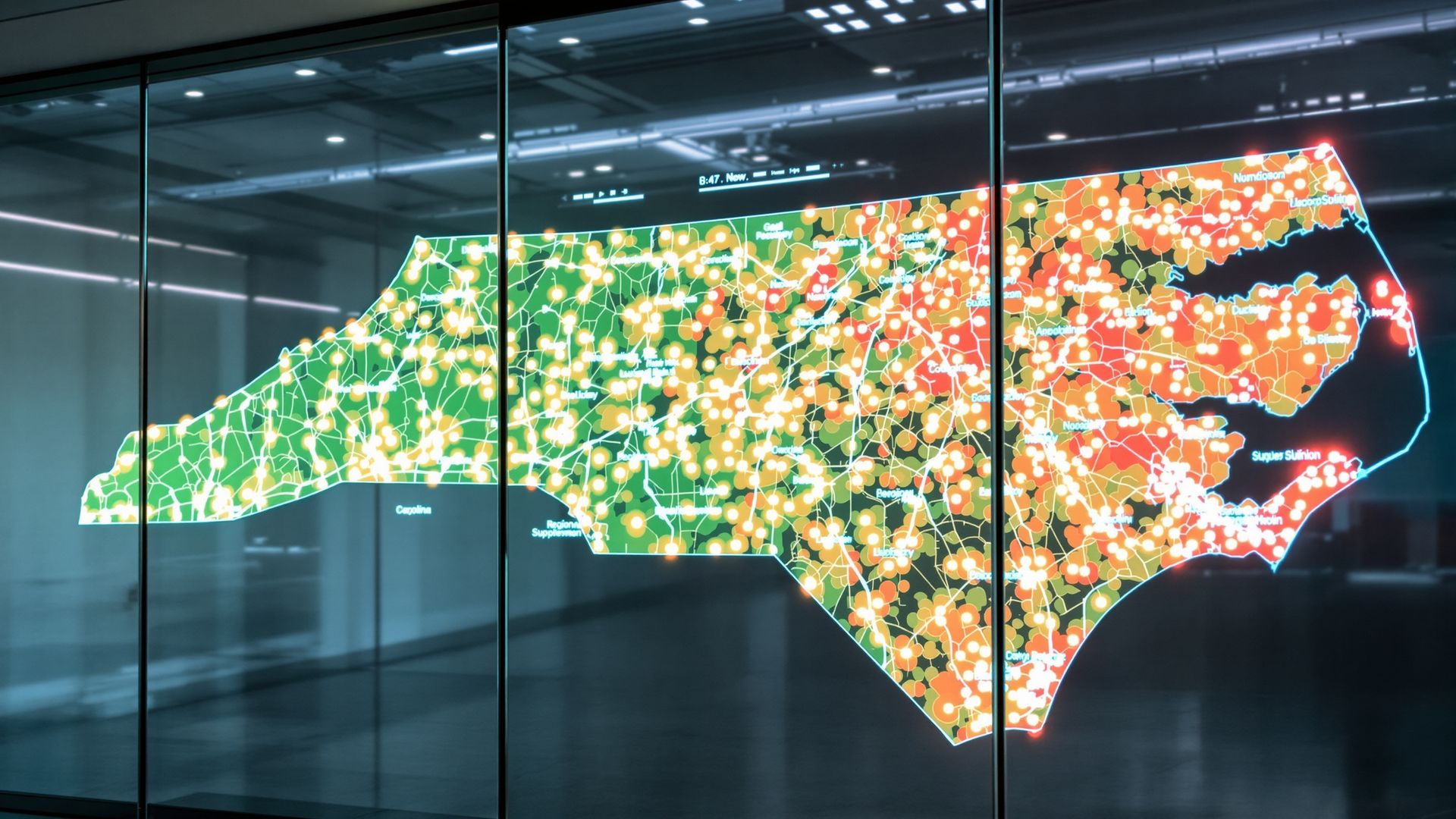

for New & Expanding Manufacturing Sites in North Carolina

Start Your Analysis Learn More

Your manufacturing investment represents significant capital and strategic positioning. But the greatest risk isn't what you can see—it's the hidden constraints that will cap your growth when you need to scale most.

The Story: In the 1990s, Intel built massive semiconductor fabs designed for peak capacity. Everything looked perfect—clean rooms, advanced equipment, skilled workforce. But when they tried to ramp up for the Pentium boom, they hit an invisible wall.

The Hidden Constraint: It wasn't manufacturing equipment or raw materials. It was maintenance scheduling. Their sophisticated equipment required more downtime than expected.

The Impact: 6-month delays, $2B in lost revenue, and market share loss to competitors who could deliver on time.

Challenge: Scaling from pilot production to full operational targets

Risk: Hidden bottlenecks preventing capacity achievement

Solution: Model complete capacity scaling scenarios

Challenge: Consistent, predictable delivery schedules

Risk: Supply chain variability disrupting commitments

Solution: Model demand variability and resilience

Challenge: Regional supply chain maturity

Risk: Supplier performance gaps limiting potential

Solution: Model supplier capacity and development

Challenge: Maintaining standards during scaling

Risk: Quality issues during ramp-up phases

Solution: Model quality performance under pressure

Comprehensive Manufacturing Ecosystem Modeling

We guarantee to identify optimization opportunities worth 10X our investment or provide a full refund. Mathematical validation of capacity improvements with proven constraint elimination methodologies.

Capacity increase = Millions in annual value

Production delay avoided = Significant value protection

Efficiency improvement = Substantial annual savings

Investment over 6 months for comprehensive analysis

Challenge: Integrating complex supply chain operations

Hidden Constraint: Inventory positioning and demand forecasting integration

Challenge: Installation project scheduling conflicts

Hidden Constraint: Installation crew and equipment conflicts

Challenge: Short product lifecycle inventory management

Hidden Constraint: Forecasting accuracy and positioning